Cutting thick metal can be a daunting task without the right blade. That’s why choosing the best sawzall blades for cutting thick metal is crucial for both professionals and DIY enthusiasts. If you want smooth, precise cuts without frequent blade changes, you need a blade that balances durability with sharpness. But which blade stands out?

Let’s explore your options. First, consider the material—high-speed steel or bi-metal blades are often the top performers. For those tackling heavy-duty projects, the best steel cutting sawzall blades can handle even the toughest jobs. And if you pair them with the best saw for cutting steel, you’ll achieve cleaner cuts with less effort. Meanwhile, the best metal cutting saw can complement your setup for larger or repetitive projects. Stick with me, because in this review, you’ll find everything you need to make an informed choice and maximize efficiency.

Top Picks

Best Metal-Cutting Precision: Diablo DS0908CF10 9" 8TPI Steel Demon Carbide Teeth Reciprocating Saw Blades

Diablo’s carbide-tipped metal-cutting blade stands out as a true performer in demanding applications. Built with TiCo Hi-Density carbide, it offers a cutting life up to 50 times longer than standard bi-metal options. This durability allows users to tackle tough materials like stainless steel, cast iron, and high-strength alloys with minimal wear. The oversized 1-inch blade body ensures each cut stays straight and controlled, reducing vibration and chatter for cleaner results. Its Perma-SHIELD non-stick coating is another advantage, keeping the blade cool under pressure while preventing corrosion and resin buildup that often slow down productivity.

From a customer perspective, this blade earns praise for delivering professional-grade results even in home or workshop settings. Many users appreciate its ability to cut through thick metals without overheating or dulling quickly, translating to fewer blade changes and lower long-term costs. However, the 8-tooth design, while excellent for heavy-duty applications, can leave a slightly rougher finish on thinner materials. Overall, Diablo’s engineering focus on carbide quality and stability makes this blade a top-tier choice for anyone needing consistent power and precision in metal cutting.

Best Extreme Metal Cutter: Diablo Steel Demon Carbide Teeth Reciprocating Saw Blades for Thick Metal

Diablo’s 8-tooth carbide-tipped metal-cutting blade is purpose-built for tackling the toughest materials with ease. Featuring the brand’s proprietary TiCo Hi-Density carbide, it provides exceptional longevity—lasting up to 50 times longer than conventional bi-metal blades. This performance makes it ideal for cutting through stainless steel, cast iron, and high-strength alloys without losing sharpness. The oversized 1-inch blade body enhances stability, minimizing vibration and ensuring each cut remains smooth and controlled. Additionally, the Perma-SHIELD coating effectively reduces heat buildup, prevents corrosion, and keeps the blade running cleaner for longer periods.

From the user’s perspective, this blade consistently delivers professional-grade cutting precision across a wide range of metalworking tasks. Many buyers note its efficiency in heavy-duty jobs, praising its ability to maintain speed and accuracy without overheating or wearing prematurely. The improved carbide-to-blade connection also boosts impact resistance, making it a reliable option for frequent use. While its 8-tooth design favors aggressive cutting power, users working with thinner or more delicate metals may notice a less refined edge. Overall, Diablo’s engineering excellence makes this blade a dependable and long-lasting choice for serious metalworkers seeking consistent, high-performance results.

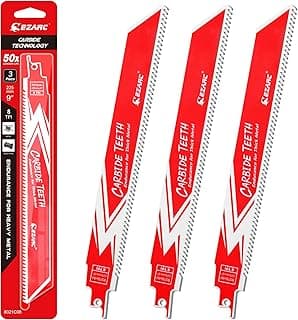

Best Precision Metal Cutter: Diablo Steel Demon Carbide Teeth Reciprocating Saw Blades

Diablo’s carbide-tipped 8-tooth metal-cutting blade is designed for professionals who demand precision and durability in every cut. Built with the brand’s signature TiCo Hi-Density carbide, it delivers excellent edge retention and strength, especially when working with medium-gauge metals. The blade’s optimized 8 TPI tooth geometry allows for smoother, cleaner finishes, making it a standout choice for precision tasks that require accuracy without sacrificing cutting speed. Its oversized 1-inch blade body adds rigidity, reducing vibration and ensuring each cut remains controlled and straight. The Perma-SHIELD coating also enhances performance by minimizing heat buildup, friction, and corrosion—key factors in prolonging blade life.

From a user standpoint, this Diablo blade is well-regarded for striking the right balance between power and finesse. Customers highlight its ability to produce clean, consistent results when cutting through common metals such as mild steel, copper, and aluminum. Many appreciate how it maintains its sharpness across multiple uses, avoiding the dulling issues typical of standard blades. The reduced vibration and stable handling also contribute to a smoother user experience, particularly for detailed metalwork. However, since it’s optimized for medium metals, it may not perform as efficiently on thicker or hardened materials. Overall, this blade earns strong marks for its precision, control, and reliable cutting performance in everyday metalworking applications.

FAQs

What is the best sawzall blade for hard metal?

When it comes to hard metal like stainless steel or thick steel beams, bi-metal blades are typically the best choice. These blades combine high-speed steel teeth with a flexible alloy steel backing, giving both toughness and durability. Look for blades with higher TPI (teeth per inch), around 18-24, to ensure smoother, more precise cuts. Carbide-tipped blades are another excellent option for extremely hard metals—they last longer and resist wear, although they may be more expensive. Always choose a blade rated for thick metal cutting to avoid breakage or uneven cuts.

Can a sawzall cut thick metal?

Absolutely. A sawzall (reciprocating saw) can cut thick metal, but the efficiency depends on the blade type, TPI, and saw power. Heavy-duty bi-metal blades or carbide-tipped blades are ideal for thicker materials. Additionally, using proper speed and firm, steady pressure is essential to prevent overheating and blade damage. Remember, cutting too quickly can cause rough edges and shorten blade life. For thicker sections, a slower, controlled motion ensures a clean, precise cut every time.

Is 18 or 24 TPI better for metal?

The number of teeth per inch (TPI) affects the smoothness and speed of your cut. An 18 TPI blade is better for cutting thicker metals because fewer teeth remove more material quickly, reducing the chance of overheating. On the other hand, a 24 TPI blade provides a smoother, more precise cut on thinner or medium metal sheets. For heavy-duty thick metal, start with 18 TPI for efficiency, then switch to higher TPI for finishing cuts if needed.

What size circular saw will cut a 4x4?

To cut a standard 4x4 post (approximately 3.5 x 3.5 inches actual size), a circular saw with a 7-1/4 inch blade is generally sufficient. Ensure the blade is designed for wood, metal, or multi-material use depending on the post type. For thicker or composite materials, a larger 10-inch or 12-inch saw may provide deeper cuts and smoother operation. Always check the maximum cutting depth of your saw and consider a high-quality blade to avoid binding or splintering.

Final Thoughts

Choosing the right blade for cutting thick metal is more than a simple purchase—it’s an investment in efficiency, precision, and safety. Bi-metal and carbide-tipped sawzall blades offer durability and clean cuts, while the correct TPI ensures the right balance between speed and smoothness. Pair these blades with a reliable saw, and even the toughest metal becomes manageable. By understanding your materials, blade options, and cutting techniques, you can tackle any thick metal project with confidence and professional results.