Choosing the best saw blade for hardwood is not as simple as picking the sharpest one. Hardwood is dense, unforgiving, and demands precision. So, how do you know which blade can handle the job without burning the wood or wearing down too quickly? Keep reading—because the details matter.

When researching options, many woodworkers also compare the best saw for cutting laminate flooring or even the best saw blade for cutting composite decking. Why? Because each material requires a different blade design and tooth count. Understanding those differences helps you avoid costly mistakes. And if you’re still searching for the best saws overall, this guide will point you in the right direction.

Let’s dive into what makes a saw blade stand out for hardwood and how you can choose the right one for your projects.

Top Picks

Best Hardwood Precision: BOSCH T307BFP 3 pc. 4-1/2 in. 12 TPI Precision

This Bosch T307BFP jig saw blade set is designed for hardwood, featuring 12 TPI for fine, precise cuts. The blades measure 4-1/2 inches and come in a set of three, offering a balance of control and durability. The brushed finish and solid rectangular shape highlight the brand’s focus on reliable performance in woodworking tasks.

From a customer’s perspective, these blades deliver accurate results on hardwood projects without splintering. Professionals often value their consistent quality and compatibility with multiple saw models. However, some users might find them less suited for materials beyond hardwood or for heavy-duty applications.

Overall, the Bosch T307BFP blades provide dependable performance for specialized woodworking. They represent solid value for those who prioritize precision over versatility.

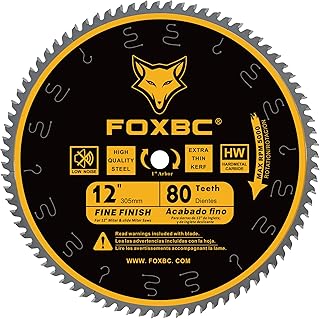

Best Fine Finish: Diablo Saw Blade for Wood - 12" x 80 Teeth

The Diablo D1280X 12-inch saw blade is built with 80 teeth, making it ideal for ultra-fine, smooth finishes on wood projects. With its brushed finish and precision-ground teeth, this blade balances clean performance and long-lasting sharpness. The lightweight plastic body and solid design help reduce vibration during operation, which contributes to greater control.

Customers often highlight the blade’s ability to deliver precise cuts on trim, plywood, and fine woodworking tasks. Experts recognize its efficiency for finishing work but note that it is less suitable for rough cutting or heavy-duty jobs.

Overall, the Diablo D1280X offers excellent performance for finish carpentry, providing strong value to users who prioritize accuracy and clean results.

Best Polished Finish: Diablo Ultimate Polished Finish Saw Blade for Wood

The Diablo D1090X 10-inch saw blade is engineered for high-end woodworking, featuring 90 ASFG teeth with a double-side grind tooth geometry. This design delivers finishes comparable to 220-grit sandpaper, producing exceptionally smooth results. Built with TiCo Hi-Density Carbide, the blade offers extended durability and up to five times longer life than standard options. Its ultra-thin kerf reduces material waste and places less strain on the tool, making cutting faster and more efficient.

Users appreciate its ability to handle hardwoods, softwoods, veneered plywood, and melamine with clean, polished cuts. Professionals note that the axial shear-face grind design helps reduce tear-out and improves accuracy, particularly for detailed finishing work. However, its specialized design makes it less practical for rough framing or general construction tasks.

Overall, the Diablo D1090X is a top-tier finishing blade that excels in precision and surface quality, making it an excellent choice for woodworkers who demand flawless results.

FAQs

What is the best tooth count for cutting hardwood?

The ideal tooth count depends on the balance between speed and smoothness. For hardwood, a blade with 40 to 60 teeth on a 10-inch saw is often recommended. Lower tooth counts cut faster but can leave rough edges. Higher counts produce smoother finishes but cut more slowly and require more power. If your goal is fine furniture work, aim for 60 teeth or higher. For general flooring or framing, 40 teeth usually suffice.

What blade to use to cut hardwood flooring?

When cutting hardwood flooring, a carbide-tipped blade is the best option. These blades stay sharp longer and resist heat buildup, which is critical for dense wood. A crosscut blade with 60 to 80 teeth on a 10-inch saw works well for clean edges. If you’re ripping boards lengthwise, use a ripping blade with fewer teeth, typically around 24 to 30, to prevent binding and overheating.

Do you need a special blade to cut hardwood?

Yes, you do. Hardwood is much denser than softwood, meaning standard blades can dull quickly or cause burn marks. A specialized blade—typically carbide-tipped with a medium to high tooth count—is designed to withstand the extra stress. These blades maintain sharpness longer and deliver cleaner cuts, saving time and reducing waste from chipped edges.

What is an 80 tooth saw blade used for?

An 80-tooth saw blade is designed for ultra-smooth cuts. It’s most often used for crosscutting hardwood, plywood, and laminates where precision is essential. For hardwood flooring, this blade minimizes tear-out and leaves a polished edge that requires little to no sanding. While it cuts more slowly than lower-tooth blades, it’s the right choice when finish quality is the priority.

What is a 40 blade used for?

A 40-tooth blade is a versatile option often called a general-purpose or combination blade. It strikes a balance between speed and finish. On hardwood, it’s suitable for both ripping and crosscutting in projects where a flawless edge isn’t critical. For tasks like rough flooring cuts or framing, a 40-tooth blade saves time without sacrificing too much quality.

Conclusion

The best saw blade for hardwood depends on your project needs. If you’re aiming for speed, a 40-tooth blade is practical. For precision, especially in flooring or fine woodworking, a 60- to 80-tooth carbide-tipped blade is ideal. Remember, hardwood demands more from your tools, so investing in the right blade saves both effort and materials. Choose wisely, and your projects will reward you with smooth, accurate cuts every time.