Choosing the best saw blade for cutting plastic can feel overwhelming with so many options on the market. Different plastics require different approaches, and the wrong blade often leads to melting, chipping, or rough edges. So, how do you pick the right one?

Let’s break it down. Whether you’re comparing the best saw blade for cutting trex decking, exploring options for the best saw blade for cutting aluminum, or just looking for a guide to the best saws overall, the right blade selection is critical. Stay with me—because once you know the key features to look for, you’ll be cutting plastic like a pro in no time.

Top Picks

Best Precision: 12 Inch 100 Tooth, Carbide Tipped Teeth, TCT Saw Blades

The 12-inch Revvstark 100-tooth TCT saw blade is engineered for versatility, cutting through wood, plastic, and composite materials with precision. Its tungsten carbide-tipped teeth resist wear and heat, while the ultra-thin laser-cut kerf ensures fast, smooth, and accurate performance. Noise-reducing perforations and thermal expansion grooves add comfort and extend blade life, making it practical for both professional and workshop use.

From a customer’s perspective, the blade stands out for its consistently clean finish and quiet operation, though some may find the arbor size restrictive and the price higher than entry-level options. Experts note that its durability and cutting efficiency justify the investment for users who value precision and long-term performance.

Overall, this blade delivers strong efficiency, reliable safety features, and professional-grade results, making it a solid choice for demanding cutting tasks.

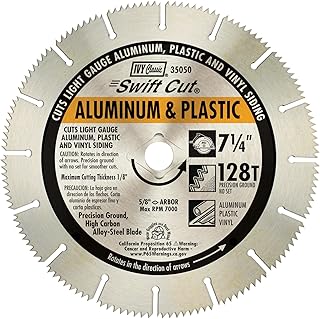

Best Metal Cuts: FOXBC 7-1/4 inch Aluminum Cutting Saw Blade 56T

The FOXBC 7-1/4 inch aluminum cutting blade with 56 teeth is designed for precise, burr-free cuts on non-ferrous metals and plastics. Built with high-density tungsten carbide, it resists wear and delivers long-lasting performance. The triple chip grind tooth geometry enhances speed and durability, while laser-cut stabilizer vents reduce vibration and noise, improving both accuracy and comfort during extended use.

Customers value its clean performance on aluminum extrusions, copper, and brass, though some note its limitations when used outside metal or plastic applications. Professionals highlight its toughness and stability, making it suitable for both corded and cordless saws.

Overall, the blade provides reliable efficiency, durability, and smooth cutting results, representing strong value for those working primarily with non-ferrous metals.

Best Fine Finish: CRAFTSMAN 7-1/4 Inch 140 Tooth Fine Finish Carbon Circular Saw Blade for Plywood

FAQs

How many teeth for cutting plastic?

The ideal number of teeth depends on the thickness and type of plastic. For thin plastic sheets, a fine-tooth blade with 60 to 80 teeth on a 10-inch blade delivers smooth, chip-free cuts. For thicker plastics, a blade with fewer teeth—around 40 to 60—helps prevent heat buildup that can melt the material. The goal is to balance smoothness with efficiency, ensuring a clean edge without burning.

What’s the best thing to use to cut hard plastic?

For hard plastics such as acrylic, PVC, or polycarbonate, the best tools are circular saws or table saws equipped with carbide-tipped blades designed for plastics. These blades reduce friction, resist heat, and produce cleaner cuts. In some cases, a fine-tooth handsaw or a jigsaw with the right blade can work, but for precision and consistency, power saws with specialty blades are the better choice.

How to cut hard plastic with a saw?

Cutting hard plastic requires proper technique to avoid cracking or melting. First, secure the plastic sheet firmly to prevent vibration. Next, use a fine-tooth blade at moderate speed. Too much speed causes heat buildup, while too little can lead to rough cuts. For thicker pieces, score the plastic lightly before making the full cut to reduce stress. Always wear safety glasses, since plastic shards can fly during cutting.

What jigsaw blade for plastic?

When using a jigsaw, select a blade labeled specifically for plastics. These blades usually have fine, evenly spaced teeth, often ground for smoother cutting. A T-shank blade with 10 to 20 teeth per inch (TPI) works well for most plastics. For softer plastics, a higher TPI blade helps avoid tearing, while for harder plastics, a slightly lower TPI reduces heat buildup. Always let the blade do the work—pushing too hard increases the risk of melting or cracking.

Conclusion

Finding the best saw blade for cutting plastic comes down to understanding the material, tooth design, and cutting method. With the right blade and technique, you can achieve clean, accurate cuts without the hassle of melting or rough edges. Whether you’re working with thin sheets or dense plastics, investing in a quality blade ensures smoother results and less wasted material. Ultimately, the right blade doesn’t just cut—it transforms your project into a professional finish.