When working with composite decking, one tool makes or breaks the project—the saw blade. Choosing the best saw blade for composite decking ensures smooth edges, minimal chipping, and long-lasting results. But here’s the thing: not all blades are created equal. Some struggle with dense materials, while others glide through with ease.

If you’ve ever researched the best saw blade for plywood, you know that material type directly affects blade choice. The same goes for decking. And while tools like the best mini hand held chain saws cordless serve other cutting needs, decking requires blades designed for precision and consistency. Wondering how this compares across categories of the best saws? Keep reading—we’ll break it all down so you can make the right call.

So, what’s next? Let’s dive into the key questions homeowners and DIYers often ask about blades for composite decking.

Top Picks

Best Fiber Cement Blade: Diablo HardieBlade Saw Blade for Fiber Cement

The Diablo HardieBlade Saw Blade uses polycrystalline diamond tips with a triple chip grind for up to 75 times longer life in fiber cement compared to carbide blades. It produces up to 50 percent less respirable dust, making the workspace safer and cleaner. Designed for heavy duty use, it handles multiple boards at once while maintaining cutting precision.

Professionals value its durability and dust control, especially for frequent fiber cement projects. Some note the higher upfront cost, but many agree it quickly pays off through extended blade life.

This blade delivers exceptional performance and long term value for contractors and remodelers who regularly cut fiber cement, standing out as one of the most reliable options on the market.

Best Composite Cutting: Diablo TrexBlade Saw Blade for Composites and Plastic

The Diablo TrexBlade Saw Blade features TiCo high density carbide teeth for extended life when cutting composite decking and plastics. Its modified triple chip grind design keeps material cool, preventing melting while ensuring clean, accurate cuts. The Perma Shield coating minimizes drag, heat, and buildup, improving efficiency and longevity. With a thin kerf design, it requires less power and delivers smooth, chip free results even on lightweight saws.

Users appreciate its reliable finish on composite decking and PVC, highlighting the clean edges and minimal chipping. Professionals note it is specialized for composites, which limits versatility, but its consistent results make it a strong investment for those materials.

This blade stands out for precision and durability in composite and plastic cutting, making it a dependable choice for deck builders and contractors seeking high quality finishes.

Best Fiber Cement Cut: Diablo HardieBlade Saw Blade for Fiber Cement

The Diablo HardieBlade 7-1/4 inch saw blade uses PCD tipped teeth with a triple chip grind, offering up to 75 times longer life than standard carbide blades. It generates up to 50 percent less respirable dust for cleaner cutting environments. Approved by James Hardie, it ensures trusted performance in fiber cement projects. With a thin kerf and anti vibration design, it provides fast, precise cuts while reducing noise and movement.

Contractors value its durability and reduced dust output, which makes it safer and more efficient for frequent fiber cement work. While it comes at a higher cost and is specialized for one material, its long life offsets the investment for professionals.

This blade delivers exceptional efficiency, safety, and reliability in fiber cement cutting, making it one of the top choices for builders and remodelers.

FAQs

What saw blade teeth for composite decking?

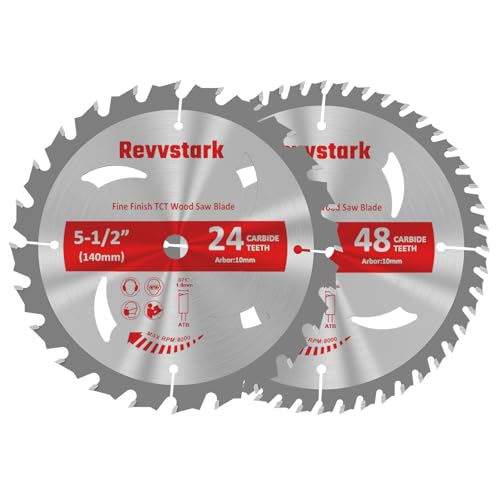

Composite decking is a blend of wood fibers and plastic, making it denser than natural wood. To cut it cleanly, a saw blade with fine, alternate-top bevel (ATB) teeth is ideal. These teeth slice through both fibers and resin smoothly, preventing tearing or melting. Typically, blades with 40 to 60 teeth provide a balance between speed and smoothness, though finer teeth are better for ultra-clean cuts.

How many tooth saw blade for composite decking?

A 40-tooth to 60-tooth blade is generally recommended. If you use fewer than 40 teeth, you risk rough edges and splintering. If you go higher than 60 teeth, you’ll get smoother cuts but at the cost of slower progress and faster blade wear. For most decking projects, a 50-tooth blade is the sweet spot—fast enough to handle multiple boards while maintaining clean results.

Do you need a special saw blade for Trex decking?

Yes, Trex and other composite decking brands benefit from specialized blades. Standard wood blades can cause chipping, excessive heat, or even blade burn. A composite-specific blade has a non-stick coating, heat-resistant design, and optimized tooth geometry to handle the density of Trex boards. Using one not only ensures smoother cuts but also extends the life of your blade and deck boards.

What blade is best for cutting Ekodeck?

Ekodeck, like Trex, is a dense composite material. The best blade for cutting Ekodeck is a carbide-tipped circular saw blade with at least 40 teeth. Carbide tips stay sharp longer, reducing the risk of tearing fibers. Look for a blade labeled as suitable for composite or laminate cutting. A 50-tooth carbide blade with ATB teeth will deliver clean, precise cuts every time.

Conclusion

Selecting the best saw blade for composite decking is not just about performance—it’s about ensuring your deck looks professional, lasts longer, and avoids costly mistakes. Whether you’re working with Trex, Ekodeck, or another composite brand, a high-quality carbide-tipped blade with 40–60 teeth will give you the results you need. Investing in the right blade from the start means cleaner edges, smoother cuts, and a project you can be proud of.