Drilling through stainless steel is no easy task—it requires the right tools, precision, and durability. If you’ve ever tried using a regular bit, you know how quickly it can dull or even snap. That’s where choosing the best drills for stainless steel makes all the difference. But wait—how do you know which options actually deliver clean, accurate holes without overheating or wearing out too fast? Here’s the deal: not all drill sets are created equal. Some of the best drills on the market are designed with advanced coatings, stronger alloys, and better tip designs to cut through even the toughest surfaces. And if you’re tackling other materials like carbon or alloy, the best drills for steel and even the best drills for metal can overlap, giving you versatile performance. Ready to discover which options truly stand out? Let’s dive in.

Top pick

Best Heat Resistance: BOSCH CO14B 14-Piece Assorted Set with Included Case

The BOSCH CO14B 14-piece set uses upgraded M42 cobalt steel with 8 percent cobalt content, making it far tougher and more heat-resistant than standard drill bits. The jobber-length design, thick web-helix structure, and surface-hardened tips help it cut efficiently through stainless steel, cast iron, titanium, and light-gauge metal.

From a customer and expert perspective, this set stands out for its ability to withstand extreme heat and maintain sharpness during heavy-duty drilling. While it comes at a higher cost and may be overbuilt for softer materials, the performance justifies the investment for those who often work with hard metals.

Overall, the BOSCH CO14B delivers excellent drilling power, reliability, and long-term value, making it a solid choice for both professionals and serious DIY users.

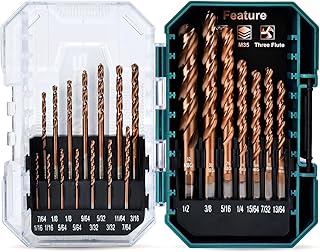

Best Precision: Crosstar M35 Cobalt Drill Bit Set

The Crosstar M35 Cobalt Drill Bit Set combines M35 cobalt alloy with a TiAlN coating that withstands up to 1,100°F, offering triple the lifespan compared to standard titanium-coated bits. The self-centering bullet point tip prevents slipping and ensures drilling accuracy as fine as 0.1 mm, making it ideal for precise work in metal fabrication, automotive, and HVAC applications. Its spiral flute clears chips efficiently, and the set comes with 21 pieces including duplicates of the most-used sizes, all stored in a durable shockproof case.

From both expert and user perspectives, this kit is praised for its durability, precision, and ability to handle hardened steel and stainless steel with ease. While it may be priced higher and isn’t designed for softer materials, its performance justifies the investment for professionals who need accuracy and reliability.

Overall, the Crosstar M35 delivers top-tier drilling performance, excellent heat resistance, and long-term value for demanding metalworking tasks.

Best Size Range: Cobalt Drill Bit Set

The Yougfin 29-piece M35 cobalt drill bit set is designed for durability and versatility, offering sizes from 1/16" to 1/2". With 5% cobalt content, these bits withstand heat and wear better than standard HSS, making them especially effective on stainless steel, alloy steel, and hardened metals. The 135° split point design reduces walking and improves cutting efficiency, while the twist grooves help remove metal shavings quickly for cleaner holes.

From a customer and expert standpoint, this set provides a solid balance of performance and variety, especially for DIYers and home repair enthusiasts who need a wide range of bit sizes in one package. However, it performs best when paired with cooling lubricant to prevent overheating and may not be the right choice for soft wood projects.

Overall, the Yougfin M35 set delivers strong performance and excellent size coverage, making it a practical and cost-effective choice for everyday drilling tasks involving tough metals.

FAQs

What is best for drilling stainless steel?

Stainless steel is a tough material that tends to harden quickly under heat and friction. To drill it effectively, you need high-quality drill bits specifically designed for hard metals. Cobalt drill bits (often M35 or M42 grade) are considered the best because they can withstand high temperatures and resist wear. Using cutting fluid or lubricant is also essential, as it reduces heat buildup, prevents bit dulling, and ensures smoother drilling. A slower drill speed with steady pressure works far better than high-speed drilling, which can damage both the bit and the material.

Are cobalt or titanium drill bits better for stainless steel?

Cobalt drill bits are generally better for stainless steel than titanium-coated ones. While titanium bits are good for softer metals and have a wear-resistant coating, the coating can wear off over time. Cobalt bits, on the other hand, are made from an alloy containing cobalt throughout the entire bit, not just the surface. This gives them superior durability, heat resistance, and cutting performance when working with hard metals like stainless steel. If you want a long-lasting solution for repeated use on stainless steel, cobalt bits are the better choice.

What is the best drill angle for stainless steel?

The drill point angle plays a major role in cutting efficiency. For stainless steel, a 135-degree split-point angle is recommended. This angle reduces walking (when the bit slips across the surface), provides a more accurate start, and allows better penetration into the hard surface without excessive force. Compared to the standard 118-degree angle, the 135-degree split point also distributes cutting pressure more evenly, which helps extend the life of the drill bit.

Can I use a regular drill on stainless steel?

Yes, you can use a regular handheld drill on stainless steel, but the results depend on the drill bits and technique. Standard drill bits designed for wood or soft metals will struggle and quickly become dull. To drill stainless steel properly, you’ll need cobalt or other high-speed steel bits rated for hardened materials. Additionally, using the right speed (low RPM), applying cutting oil, and maintaining steady pressure are key. Without these precautions, a regular drill may overheat, cause excessive wear, or fail to penetrate the steel.

Conclusion

Choosing the best drills for stainless steel comes down to durability, precision, and the right drilling technique. Stainless steel is a notoriously tough material, so investing in high-quality cobalt drill bits with a 135-degree split point design is often the smartest choice. Pairing the right bits with slow drilling speeds, steady pressure, and cutting fluid will not only protect your tools but also deliver cleaner, more accurate holes. While a standard drill can handle the job, the right bit set makes all the difference in performance and longevity. In the end, matching the right equipment to the challenge ensures that even the toughest stainless steel projects can be tackled with confidence.