Choosing the right track guide transforms a handheld circular saw into a precision cutting tool. If you frequently rip sheet goods, trim long boards, or need perfect edge cuts, a well-made track rail reduces chatter, eliminates tear-out, and speeds setup. But not all systems deliver the same value. For quick-shop decisions, consider compactness, repeatability, and how smoothly the saw rides the rail. For example, if portability matters, look at the best compact circular saw options that pair well with short rails. If you focus on long, straight rips, a dedicated best circular saw rip guide may be the smarter investment. And if you want general versatility, compare models that work with the best circular saw platforms on the market. Here’s a clear, practical breakdown to help you decide.

Top Picks

Best Extension Reach: Milescraft 1408 Guide Rails – 55 Inch Rail Extensions

The Milescraft 1408 Guide Rails are designed for woodworkers who need to extend the cutting range of their Milescraft 1409 Track Saw Guide. Measuring 55 inches per rail, this extension system can increase your total cutting capacity to more than 8 feet, making it ideal for handling large sheet materials or long rip cuts. The all-aluminum construction provides excellent rigidity and stability, reducing flex for more consistent results during precision cuts. The included connectors ensure a seamless link between rails, maintaining alignment and preventing movement during operation. Additionally, the red cutting strip acts as both a visual guide and a splinter guard, resulting in cleaner edges with minimal chipping.

From a customer perspective, this set feels sturdy and purpose-built for demanding woodworking projects. Many users appreciate how easily it integrates with their existing TrackSawGuide setup, extending functionality without compromising accuracy. The added length helps them cut full plywood sheets in one pass, a major advantage for cabinetmaking or furniture building. However, a few note that it’s not compatible with other track saw brands, which limits flexibility for mixed-tool workshops. Despite a slightly higher cost compared to universal rails, most users find the solid construction and improved precision well worth the investment.

Best All-in-One Bundle: WEN Plunge Cut Circular Saw Bundle with 100-Inch

The WEN Plunge Cut Circular Saw Bundle offers a versatile cutting solution for professionals and DIY users seeking accuracy, power, and convenience in one package. The 10-amp, 6.5-inch plunge saw delivers consistent performance for deep cuts up to 2-1/3 inches, while the 24-tooth carbide-tipped blade ensures clean, smooth results on a variety of materials. Its adjustable bevel function allows for precise 45-degree cuts in boards up to 1-5/8 inches thick, making it suitable for cabinetry, flooring, and panel trimming.

The included 100-inch track system—two 50-inch rails connected by adapters—provides over 8 feet of guided cutting length. The aluminum rails feature a non-slip rubber lip that helps control dust and protect the work surface. The base of the saw glides smoothly along precision grooves, minimizing drift and ensuring accurate, straight cuts every time. Four set screws in the adapter set keep the rails tightly aligned for enhanced stability.

From a user standpoint, this bundle offers exceptional value for its completeness and performance. Customers appreciate the ease of setup and how the saw tracks effortlessly along the guide for consistent results. Many find the plunge mechanism intuitive and the motor powerful enough for both hardwood and plywood. Some users, however, mention that purchasing clamps separately adds to the total cost and that dust collection could be improved when cutting indoors. Overall, the WEN Plunge Cut Circular Saw Bundle stands out as a dependable, well-balanced system for precise and extended cutting tasks.

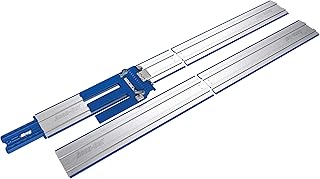

Best Splinter-Free Precision: Kreg ACS430 Adaptive Cutting System 62-inch Guide Track

The Kreg ACS430 Adaptive Cutting System Guide Track is a precision-engineered solution for woodworkers who value accuracy, safety, and smooth performance. Measuring 62 inches, this aluminum guide rail is designed to deliver splinter-free, straight cuts whether used alone or as part of Kreg’s full Adaptive Cutting System. Its anti-chip strip minimizes tear-out along the cut line, resulting in professional-quality edges on both hardwood and plywood. The zero-offset design aligns perfectly with the blade’s path, ensuring every cut lands exactly where intended without the need for additional marking or measuring.

One of its standout features is the secure, clamp-free setup. The built-in anti-slip strips keep the track firmly in place, saving time and simplifying the cutting process. For larger panels or full-sheet cuts, the track can easily be expanded by connecting two rails, offering flexibility for a range of projects. Constructed from durable aluminum, it provides both rigidity and long-term reliability.

From a customer’s viewpoint, this guide track feels premium and performs with impressive consistency. Many users highlight the convenience of the clamp-free system and the flawless finish of their cuts, even on veneered materials. The smooth glide and tight blade alignment make it a favorite for cabinetmakers and finish carpenters. Some note, however, that achieving full 8-foot cuts requires purchasing a second track, which raises the overall cost. Still, most agree that the Kreg ACS430 delivers exceptional precision and build quality, making it a top-tier choice for serious woodworking professionals.

FAQs

Can you use a track saw guide with a circular saw?

Yes — many circular saws can be used with track-style guides, but compatibility and performance depend on the rail design and the saw’s base. There are two common approaches:

-

Dedicated track saws: These are purpose-built with bases that mate directly to tracks; they seal against the rail for excellent accuracy. Using a circular saw here usually isn’t possible without an adapter.

-

Adapter or universal guide systems: Several manufacturers make universal guide rails or adapters that clamp a standard circular saw to the track. These adapters either attach to the saw’s base or use a sled that the saw rides in. When using an adapter, expect slightly less precision than a dedicated track saw but still much better control than freehand.

What to watch for:

-

Shoe flatness and alignment: The saw’s base plate must sit flat and align with the rail. Any wobble translates to cut error.

-

Blade orientation & guard interference: Some circular saws (left- or right-blade orientation) may block adapter fit or rail contact.

-

Kerf offset: Most rails are designed so the edge of the rail corresponds to the blade kerf after accounting for an offset; verify the manufacturer’s offset so you mark and cut accurately.

-

Safety and dust control: Dedicated track saws often provide better dust extraction and integrated anti-kickback; adapters may be more exposed.

In short: yes, but test the specific saw + rail pairing and adjust for kerf and guard clearance before relying on it for critical work.

What is the best track saw system?

There isn’t a single “best” system for everyone — it depends on priorities: precision, portability, price, or accessory ecosystem. Evaluate systems by these factors:

-

Rail straightness and jointing: High-end rails are extruded or machined for consistency; cheaper rails can have cumulative errors over long runs. Look for rails with a clean, straight reference edge and robust anti-slip features.

-

Saw mounting/interface: Dedicated track saws that clip or seal to rails provide the best repeatability. If you prefer using multiple saw brands, choose a universal rail system with widely supported adapters.

-

Length options and expandability: The best systems offer modularity — short rails for transport and joiners to create longer tracks without loss of alignment.

-

Clamping and anti-slip: Built-in clamps or effective anti-slip strips prevent rail movement. Systems that include quick clamps or have integrated clamp points save setup time.

-

Dust extraction and blade protection: Better systems channel dust away and protect the blade and rail, improving cut quality and longevity.

-

Accessories and support: Accessories like splinter strips, measuring stops, parallel fences, and carrying cases matter if you’ll use the system frequently.

Choose the system whose strengths align with your work: professional woodworkers will favor absolute accuracy and accessories; jobsite carpenters will prioritize portability and durability.

Are circular saw guide rails worth it?

Yes — for many users they are worth the investment. Benefits include:

-

Significant accuracy gains: A guide rail converts a handheld saw from a freehand tool to a guided one, turning long, straight cuts into repeatable, square edges.

-

Time savings on layout and finishing: Less time spent marking, clamping, or hand-planing saves labor and reduces material waste.

-

Reduced tear-out: Using a splinter strip or zero-clearance edge on the rail minimizes fiber lift on plywood or veneered panels.

-

Improved safety: Controlled travel and reduced lateral forces lower the chance of kickback or binding.

Counterpoints to consider:

-

Cost vs. frequency: If you rarely make long straight cuts, a rail might be unnecessary.

-

Set-up time for small cuts: For short, quick cuts a rail can be overkill — but for repeatable tasks it pays back quickly.

-

Compatibility hassles: Mismatched saws and adapters add complexity; confirm fit before buying.

Overall, for anyone working with sheet goods, doing repeated rips, or needing clean crosscuts, guide rails are generally worth it.

Are track saw parallel guides worth it?

Track saw parallel guides — devices that maintain a fixed offset from a reference edge — are valuable accessories and often worth adding depending on tasks:

-

Precision ripping: Parallel guides let you set a precise distance from the board edge for repeated rips without remeasuring each pass.

-

Repeatability: They speed up production work by providing quick stops and fences for similar-width pieces.

-

Versatility: Some parallel guide systems double as edge guides for sawing freehand or as jigs for cutting narrow strips safely.

Limitations:

-

Added setup: Attaching and calibrating a parallel guide takes time. For one-off cuts the overhead may not be worthwhile.

-

Compatibility: Not all guides fit all rails or saw models; ensure the guide works with your chosen rail.

When you have repeated layout needs or production-style workflows, parallel guides enhance accuracy and throughput and are typically worth the small additional expense.

Final Thoughts

A track guide converts a standard circular saw workflow into a precision cutting system. Decide first whether you need the absolute accuracy of a dedicated track saw or the flexibility of an adapter-enabled circular saw track. Evaluate rail straightness, clamping, modular lengths, and dust control to match the system to your shop or jobsite. For regular sheet goods or repetitive rips, guides and parallel fences repay their cost quickly through improved accuracy, speed, and less waste. Choose the combination that aligns with your priorities — portability, precision, or price — and test the saw-to-rail fit before committing.