Cutting plastic can be tricky if you don’t have the right tools. That’s why choosing the best circular saw blade for cutting plastic is essential for anyone from DIY hobbyists to professional craftsmen. You want a blade that glides through acrylic, PVC, or polycarbonate without melting or chipping the edges. But there’s more to consider. For example, if you’re working on flooring projects, the best circular saw blade for laminate flooring can handle delicate surfaces, while a best battery operated circular saw provides portability for outdoor or on-site tasks. Even when selecting a general-purpose tool, knowing how to pair it with the best circular saw blades can drastically improve your results. Keep reading, because we’ll dive into expert tips, key features, and essential guidance to make every cut precise and effortless. Here’s everything you need to know to master cutting plastic with confidence.

Top Picks

Best Durability: FOXBC 7-1/4 inch Aluminum Cutting Saw Blade 56T

The FOXBC 7-1/4 inch aluminum saw blade stands out for professional and DIY users working with non-ferrous metals such as aluminum, copper, and brass. Its 56-tooth design with Triple Chip Grind (TCG) geometry delivers fast, precise, and clean cuts while minimizing burrs. Constructed from high-density tungsten carbide, the blade offers impressive wear-resistance and long-lasting performance. Laser-cut stabilizer vents help reduce vibration and noise during operation, contributing to smoother, more accurate cuts. Compatible with both corded and cordless saws, this blade maintains cutting efficiency even under frequent on-the-job use.

From a user perspective, many appreciate the clean cuts and durability, noting that it reduces the need for repeated finishing work. Some users mention that its weight is noticeable compared to standard blades, and its effectiveness is limited to non-ferrous metals, making it less versatile for mixed-material projects. Overall, customers value the FOXBC blade for its precision, toughness, and reliability in professional metal-cutting applications.

Best Precision: CRAFTSMAN 7-1/4 Inch 140 Tooth Fine Finish Carbon Circular Saw Blade

The CRAFTSMAN 140-tooth compact saw blade is designed for users who prioritize precision and clean finishes in woodworking projects. Its fully-hardened plate ensures that cuts remain true over time, minimizing the need for repeated adjustments. Precision-ground teeth provide smooth, accurate cuts, making it suitable for fine woodworking or trim work. The heavy-gauge high carbon steel construction extends the blade’s lifespan, while the fully flattened plate aids in fast, consistent cutting.

From a user perspective, the blade is praised for maintaining accuracy even with frequent use, producing smooth edges without chipping. Some users note that its compact size and high tooth count make it less ideal for cutting thicker or harder materials, so it is best suited for light to medium-duty tasks. Overall, customers appreciate the reliability, sharpness, and long-lasting performance of this CRAFTSMAN blade for precision cutting.

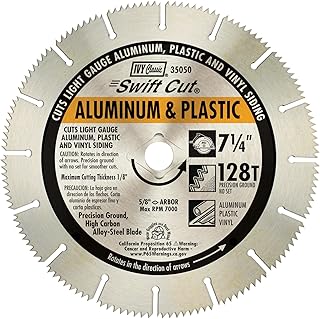

Best Plastic Cutting: IVY Classic 36350 Laser Carbide 7-1/4-Inch 60 Tooth Solid Surface

The IVY Classic 7-1/4 inch saw blade is tailored for precision cutting of plastics, acrylic sheets, Plexiglas, and solid surface materials like Corian. Its 60-tooth design features triple chip ground large C4 modified tungsten carbide teeth, ensuring clean, burr-free cuts. The fully hardened body, rated Rockwell Hardness 40–43 HRC, provides industrial-level durability and long-lasting performance. Expansion slots are integrated into the blade to reduce heat build-up and prevent warping during extended cutting sessions. The 5/8-inch diamond knockout arbor and 0.110-inch kerf make it compatible with most standard saws, while the -6-degree hook angle supports controlled, smooth feeding.

Users consistently highlight the blade’s precision and clean finish when working with plastics, noting minimal chipping and reduced finishing work afterward. Some mention that the blade is heavier and best suited specifically for non-wood materials, so it may not be the most versatile option for general-purpose use. Overall, the IVY Classic blade is highly regarded for its efficiency, durability, and reliability in professional or hobbyist projects involving plastics and solid surfaces.

FAQs

What is the best circular saw blade for cutting plastic?

The best circular saw blade for cutting plastic is specifically designed with a combination of high tooth count, alternate top bevel (ATB) or triple chip grind (TCG) patterns, and a fine kerf. These features reduce heat buildup and minimize melting. Blades made from carbide-tipped steel are ideal, as they stay sharp longer and resist chipping. Look for a blade with 60–80 teeth for smaller diameter saws and 80–120 teeth for larger saws, depending on the thickness and type of plastic. Additionally, blades designed for multi-material use can be versatile, allowing you to cut plastic along with softwoods or laminates without compromising performance.

Can you cut plastic with a circular saw?

Yes, plastic can be safely cut with a circular saw, but you need the right blade and technique. Avoid high speeds that generate excess heat, as this can melt the plastic and create rough edges. Secure the plastic sheet firmly to prevent vibration, and use a straightedge guide to maintain a clean, straight cut. Applying masking tape along the cut line can further prevent chipping. Always wear protective gear, including eye protection, because plastic shards can fly during cutting. With the right blade and careful handling, a circular saw can efficiently produce precise, professional-looking cuts in plastic sheets of various thicknesses.

What saw is best for cutting plastic?

The best saw for cutting plastic depends on the thickness and type of plastic. For thin sheets (up to 1/4 inch), a standard circular saw with a fine-toothed blade works perfectly. For thicker or harder plastics, a battery-operated circular saw or a table saw with adjustable speed settings may be preferable to reduce melting and ensure control. Avoid using jigsaws or reciprocating saws with standard blades, as they tend to create rough edges or cracks. Precision, stability, and blade choice are more important than the saw itself when aiming for clean, smooth cuts.

How many teeth for cutting plastic?

The number of teeth is critical for smooth, chip-free cuts. For circular saws:

-

Thin plastic sheets (1/8"–1/4"): 60–80 teeth

-

Thicker plastic (1/2"–1"): 80–120 teeth

Finer teeth mean slower, cleaner cuts, while fewer teeth may be faster but risk chipping or melting. Triple chip grind (TCG) or alternate top bevel (ATB) blades are recommended for plastics, as their design distributes heat and reduces friction. Always match the blade tooth count to the plastic’s thickness and the saw’s speed for optimal results.

Final Thoughts

Choosing the best circular saw blade for cutting plastic ensures clean, precise, and safe cuts across various projects. Focus on carbide-tipped, fine-toothed blades with appropriate tooth geometry, secure your material, and use proper technique to prevent melting and chipping. By understanding tooth count, blade types, and saw compatibility, you can confidently tackle any plastic cutting task. With the right setup, your circular saw becomes a reliable tool for professional-grade plastic work.