Cutting Lexan can be tricky without the right tools. If you’ve ever tried a standard saw, you know how easily polycarbonate sheets can chip, crack, or melt. That’s why finding the best circular saw blade for cutting Lexan is essential for both DIY enthusiasts and professionals. But don’t stop there—choosing the right blade can also impact how well you handle other materials. For example, the best circular saw blade for cutting OSB ensures smooth, splinter-free edges, while the best circular saw blade for cutting granite delivers precision on dense, tough surfaces. And, of course, having a reliable best circular saw in your workshop makes all the difference. Keep reading because we’ll break down exactly what to look for, how to use it safely, and tips for achieving professional results with Lexan sheets.

Top Picks

Best Precision: FOXBC 3 Inch Circular Saw Blade 24T Carbide Cuts for Wood, Plastic

The FOXBC 3-inch carbide circular saw blade stands out with its ultra-thin kerf design, enabling faster, cleaner cuts while reducing strain on both the saw and the user. With 24 ATB teeth crafted from high-density tungsten carbide, it delivers durability and long-lasting sharpness suitable for cutting wood, plastic, PVC, acrylic, aluminum, and other soft materials. The blade is designed for versatility, fitting a wide range of popular 3-inch saws including Dewalt 20V cordless, Dremel Saw-MAX, RotoZip, Milwaukee 2522-20, Ryobi PSBCS02 One+, Ridgid R87547B, and Worx 20V models. Its compact 3-inch size makes it easy to handle and control, especially for precision cuts.

From a customer perspective, users appreciate the smoothness of the cut and the reduced vibration thanks to the ultra-thin kerf, which helps maintain accuracy. Many highlight its ability to handle multiple materials without frequent blade changes, making it a convenient option for DIY projects and light workshop tasks. However, some note that the small diameter limits its capacity for larger or more demanding jobs, and it’s best suited for lighter-duty cutting rather than heavy industrial use. Overall, it balances precision, durability, and versatility in a compact, user-friendly package.

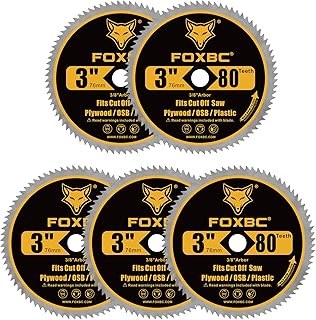

Best Finish: FOXBC 3 Inch Carbide Circular Saw Blade 36 Tooth for Wood, Plastic, PVC, Acrylic

The FOXBC 3-inch carbide circular saw blade with 36 teeth is engineered for precision and smoothness, making it ideal for finish cuts on various materials including wood, plywood, fascia, OSB, hardboard siding, PVC, acrylic, and aluminum. Its ultra-thin kerf design allows faster, cleaner cuts while reducing strain on both the saw and the operator, providing better control and accuracy. Constructed from high-density tungsten carbide, the blade offers long-lasting durability and resistance to wear, maintaining sharpness even with frequent use. The 36-tooth configuration strikes a balance between cutting speed and a fine, polished finish, perfect for detailed or jobsite finish work.

From a customer perspective, users value how smoothly the blade cuts through multiple materials without chipping or splintering, making it well-suited for finish carpentry and detailed DIY projects. Its broad compatibility with popular 3-inch saws—including Dremel Saw-MAX, RotoZip, Ridgid R87547B, Milwaukee 2522-20, Ryobi PSBCS02 One+, Dewalt 20V cordless, and Worx 20V—adds versatility. Some users note the small diameter can limit cutting depth for larger materials, and it is not meant for heavy-duty framing or industrial-scale work. Overall, it provides precise, clean cuts in a compact, durable package, appealing to both hobbyists and professionals focused on high-quality finishes.

Best Precision: CRAFTSMAN 7-1/4 Inch 140 Tooth Fine Finish Carbon Circular Saw Blade for Plywood

The CRAFTSMAN 140-tooth carbon steel circular saw blade is designed to deliver precise, clean cuts across a variety of woodworking tasks. Its fully-hardened plate ensures that cuts remain true over time, while precision-ground teeth provide smooth, accurate performance. Made from heavy-gauge high-carbon steel, the blade combines durability with extended life, making it reliable for frequent use. The fully flattened plate also aids in cutting speed and accuracy, reducing wobble and producing consistent results across different types of wood and plywood.

From a customer perspective, users appreciate the combination of precision and longevity, noting that the blade maintains sharpness longer than many standard options. The high tooth count allows for fine, clean cuts, especially on finish work or detailed woodworking projects. Some users point out that the larger 9-inch size can be less convenient for portability and that it is primarily optimized for wood and similar materials rather than metals or plastics. Overall, the blade is a dependable choice for woodworkers seeking accuracy and durability in their circular saw setup.

FAQs

Can I cut Lexan with a circular saw?

Yes, you can cut Lexan with a circular saw, but certain precautions are critical. Lexan is a type of polycarbonate, which is prone to chipping and cracking if cut too aggressively. Use a blade specifically designed for plastics, ideally with a high tooth count (around 80–100 teeth for a 7-inch blade). Make sure to secure the sheet firmly, use a slow feed rate, and avoid excessive pressure. Cutting at high speed may generate heat, causing melting along the edges. Always wear safety glasses and consider using a sacrificial board underneath to prevent blowout on the bottom side.

What type of circular saw blade to cut polycarbonate?

The ideal blade for polycarbonate, including Lexan, has the following characteristics:

-

High tooth count: More teeth produce cleaner cuts. A blade with 80–100 teeth works well.

-

Triple chip grind (TCG): This tooth design alternates flat and angled teeth to reduce chipping.

-

Fine kerf: Thinner blades reduce the material removed, minimizing stress on the sheet.

-

Carbide-tipped teeth: Durable and long-lasting, they maintain sharpness for multiple cuts.

Avoid blades designed for wood or metal alone, as they can cause cracking or rough edges on polycarbonate. Using the right blade ensures precision and extends the life of your saw.

What's the best way to cut Lexan?

For smooth, professional results:

-

Secure the sheet: Clamp Lexan to a stable surface to prevent vibrations.

-

Mark your cut: Use a fine-tip marker or masking tape to guide the saw.

-

Feed rate and speed: Move slowly and steadily. Rapid feeding can cause chipping or melting.

-

Use a sacrificial board: Placing a scrap piece underneath prevents blowout at the exit edge.

-

Finish the edges: After cutting, light sanding or filing smooths minor burrs.

Following these steps ensures straight, clean edges without damaging the sheet or your tools.

What is the best blade for cutting stone veneer?

Cutting stone veneer requires a completely different approach. Use a diamond-tipped masonry blade designed for circular saws. These blades handle hard materials, providing clean cuts without excessive dust or chip damage. Key features:

-

Continuous rim or segmented rim depending on wet or dry cutting

-

Compatible with standard circular saws, preferably with adjustable depth

-

Slower feed rate to avoid overheating and blade wear

While not related to Lexan, understanding this helps differentiate between blades for plastics and harder materials, ensuring you never compromise your project’s quality.

Final Thoughts

Choosing the best circular saw blade for cutting Lexan is essential for clean, chip-free cuts. Prioritize a high-tooth-count, carbide-tipped blade with a triple chip grind, and follow proper cutting techniques like slow feed rate and secure clamping. By understanding the right tools and methods, you can handle polycarbonate sheets with confidence while protecting both the material and your saw. Remember, the right blade makes all the difference, whether you’re working on Lexan, OSB, or even stone veneer in other projects.