Cutting plywood cleanly can be tricky—especially with thicker sheets like 3/4-inch panels. That’s why choosing the best circular saw blade for 3 4 plywood is crucial if you want smooth, accurate cuts without frayed edges. But here’s the catch—different projects demand different blades.

So, how do you find the right one? Keep reading, because we’ll walk you through what matters most: tooth count, blade design, and cutting performance. And if you’re tackling various materials, check out guides on the best circular saw blade for cutting vinyl, the best small handheld circular saw, and the best circular saw for versatility.

Let’s dive in—your next cut could be your cleanest yet.

Top Picks

Best Smooth-Cut Performance: FOXBC 7-1/4 Inch 140 Tooth Fine Finish Carbon Circular Saw Blade for Plywood

The FOXBC 7-1/4 inch circular saw blade stands out for its exceptional smoothness and precision, especially when cutting plywood, OSB, paneling, and similar sheet materials. With 140 ultra-fine teeth and a thin 0.086-inch kerf, it delivers fast, clean cuts without splintering or tear-out, even on delicate veneers or laminates. The high-speed steel construction enhances durability, allowing the blade to maintain sharpness over time. Expansion slots help manage heat and prevent warping during continuous operation, making it a reliable option for both DIY projects and remodeling tasks.

From a user’s perspective, this blade is highly appreciated for producing furniture-grade finishes with minimal sanding afterward. Many find it ideal for cabinetry, trim work, and panel installations where precision matters most. However, some note that the fine-tooth design limits its effectiveness on thick or dense hardwoods, where slower feed rates and potential blade wear can occur. Overall, the FOXBC HSS circular saw blade offers excellent value and performance for anyone prioritizing smooth, accurate cuts on lighter materials.

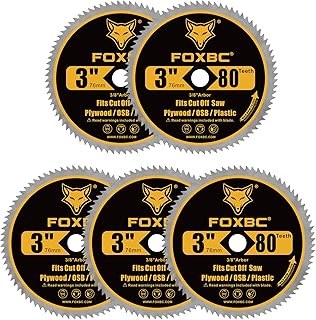

Best Compact Precision Cut: 3 Inch Circular Saw Blade 24T (Tungsten Carbide Tooth) Compatible

The YOKOCUT 3-inch circular saw blade is engineered for precision, control, and versatility in compact cutting applications. Featuring 24 tungsten carbide teeth and a slim 1.7-millimeter profile, it achieves smooth, accurate cuts through wood, plywood, OSB, veneer, and even plastics. The ultra-thin kerf minimizes resistance, allowing users to maintain steady control and reduce strain on both the saw and the operator. Its universal compatibility with popular 3-inch saws—from Dremel and Dewalt to Milwaukee and Worx—adds to its practicality for professionals and hobbyists alike.

Users consistently highlight the blade’s ability to deliver crisp, clean edges with minimal chipping, even on fine materials or trim work. The tungsten carbide construction holds its edge well, offering a balance of speed and longevity that suits repeated daily use. However, its compact size limits cutting depth, making it less effective for thick lumber or heavy framing tasks. Overall, the YOKOCUT 3-inch carbide blade provides dependable performance and precision in a small, durable form—ideal for detailed cutting and finishing projects.

Best Precision Control: CRAFTSMAN 7-1/4 Inch 140 Tooth Fine Finish Carbon Circular Saw Blade

The CRAFTSMAN 140-tooth circular saw blade is designed for accuracy and consistency in fine woodworking applications. Constructed from heavy-gauge high-carbon steel, it offers durability while maintaining a true, stable cut. Its fully-hardened, flattened plate minimizes wobble, ensuring every pass stays straight and clean. The precision-ground teeth produce smooth edges with minimal tear-out, making it ideal for plywood, veneers, and light panel materials where finish quality matters.

Customers appreciate the blade’s balance and control, noting how effortlessly it maintains accuracy through repeated use. The fully-hardened construction adds rigidity, reducing vibration and extending cutting precision over time. While it performs best on softer materials, users mention that frequent sharpening may be needed when cutting dense hardwoods or composites. Overall, the CRAFTSMAN carbon steel blade delivers reliable precision and value for those focused on smooth, clean cuts in general woodworking tasks.

FAQs

What Type of Circular Saw Blade Is Best for Plywood?

For cutting plywood, a fine-tooth carbide-tipped blade is your best choice. Plywood’s layered veneer structure tends to chip easily, so a blade with 60 to 80 teeth on a 7-1/4-inch diameter saw delivers the cleanest cuts. The fine teeth reduce tear-out on both the top and bottom surfaces, leaving a smooth edge ready for finishing.

Opt for an alternate top bevel (ATB) tooth configuration. This means each tooth is angled alternately left and right, slicing through wood fibers cleanly rather than tearing them. For cabinet-grade plywood or visible cuts, a higher tooth count (up to 100) may produce near-perfect results with minimal sanding required.

What Should a Circular Saw Blade Designed for Cutting Plywood Have?

A blade designed for plywood should have three essential features:

-

High Tooth Count: At least 60 teeth for 7-1/4-inch blades ensures fine, splinter-free results.

-

Carbide-Tipped Teeth: Carbide stays sharper longer than steel, even through resinous layers.

-

Thin Kerf Design: A thinner blade removes less material, requiring less power and producing smoother cuts.

Additionally, anti-vibration slots reduce noise and prevent wobble, which is vital for precision. If you’re using a circular saw without a table, pair it with a guide rail to maintain straight cuts and protect plywood surfaces.

Will a 6 1/2 Circular Saw Cut a 2x4?

Yes, a 6 1/2-inch circular saw can cut a 2x4—though just barely. The blade typically offers a maximum cutting depth of about 2 1/8 inches at 90 degrees, which is enough to slice cleanly through a standard 1.5-inch-thick 2x4 in one pass.

However, keep in mind that angle cuts or bevels may require a second pass since the depth of cut decreases when tilted. If you frequently cut thicker materials, upgrading to a 7-1/4-inch saw provides greater flexibility and power for framing or deck work.

What Is a 140-Tooth Circular Saw Blade Used For?

A 140-tooth circular saw blade is built for ultra-fine finish cuts, not speed. It’s commonly used for cutting veneers, laminate, melamine, and thin plywood panels where precision is critical.

The high tooth count ensures each tooth removes very little material, resulting in a glass-smooth finish with virtually no tear-out. This makes it ideal for furniture-grade projects or finishing work, where surface quality matters more than cutting speed. While these blades wear faster under heavy-duty conditions, they’re unbeatable for achieving a clean, professional appearance.

Final Thoughts

Choosing the best circular saw blade for 3 4 plywood is about balancing precision, durability, and efficiency. Fine-tooth carbide blades—especially those with an ATB pattern and thin kerf—deliver the cleanest results across plywood and other engineered woods.

Whether you’re crafting cabinets or cutting sheets for home renovation, investing in the right blade saves time, reduces rework, and elevates the overall quality of your projects. Remember: in woodworking, the cut defines the craftsmanship.